20 years of sustainable impact

20 years of sustainable impact

STAR4D celebrates anniversary

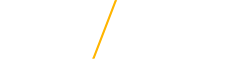

In the world of industry, innovation often arises from the unlikeliest of places. In 1993, a group of forward-thinkers within the Iowa Waste Reduction Center embarked on a journey that would revolutionize painter training and environmental responsibility. What began as an initiative to improve Iowa’s body shops eventually evolved into something much greater — the Spray Technique Analysis and Research program, known affectionately as STAR.

It was a time when the automotive industry was grappling with the environmental implications of its practices, particularly in painting processes. STAR sought to address this issue by developing cutting-edge techniques and tools to improve spray coating processes, reduce pollution and promote environmental sustainability.

The Paint Application & Coating Education facility, located in the Cedar Falls Industrial Park, was established in 1999 to provide a dedicated space for STAR research and training.

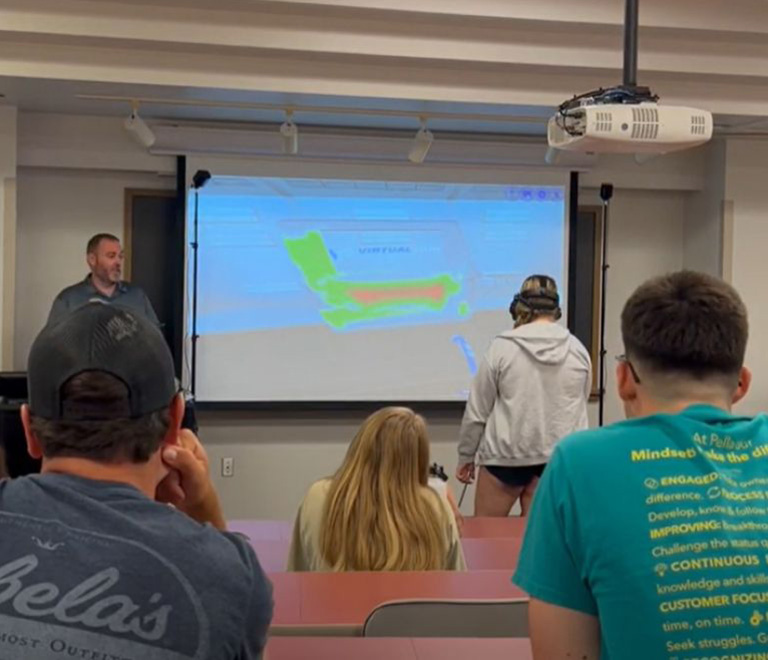

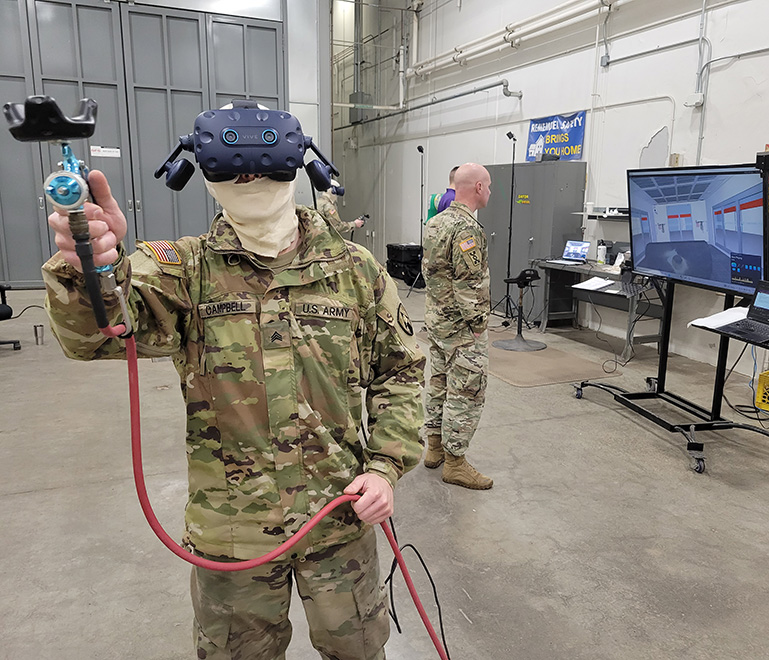

The Department of Defense began taking a closer look at the implications of corrosion on military assets. It was identified that the cost of corrosion to a military department was in the billions of dollars annually, and severely impacted the ability to be mission ready. In response, STAR underwent a transformation becoming Spray Technique Analysis and Research for Defense (STAR4D). This evolution allowed the program to serve a broader range of industries, including defense, while maintaining its commitment to reducing environmental impact.

In the span of two decades, STAR4D has demonstrated key returns on investment such as a 10% increase in painter efficiency, a 10% decrease in paint usage and a 10-25% reduction in rework, just to name a few. From its inception as a regional initiative focused on industrial painter training, STAR4D has evolved into a globally recognized program with a profound impact on multiple industries, from automotive to aerospace to defense. Its commitment to environmental sustainability, innovation and precision training has transformed the way we approach painting processes.