New fabric printer speeding up TAPP clothing production

New fabric printer speeding up TAPP clothing production

Fabric printing in UNI’s Textiles and Apparels Program just hit double time.

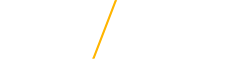

The program recently acquired a Mutoh ValueJet digital fabric printer that will print fabric for student projects at nearly twice the speed of the previous model, giving students more time to design and assemble their fashion projects and gain valuable hands-on experience in a program that has seen graduates go on to leadership roles at clothing-industry giants like Cabelas and Macy’s.

“There aren't a lot of programs in the country such as ours that have a printer that is completely accessible in classes to undergrad students,” said Sharon Mord, a TAPP instructor. “It’s a very hands-on teaching tool. You can talk about fabric printing, you can look at pictures, you can even watch videos, but doing it is just so much more impactful for the students.”

The printer ran its first job on Monday, producing a pattern for men’s cargo pants designed by senior Rachel Funkhauser.

“I think this is really special that we get to go from designing a print on the computer to actually printing it and then processing the fabric to then using that fabric for one of our projects,” Funkhouser said.

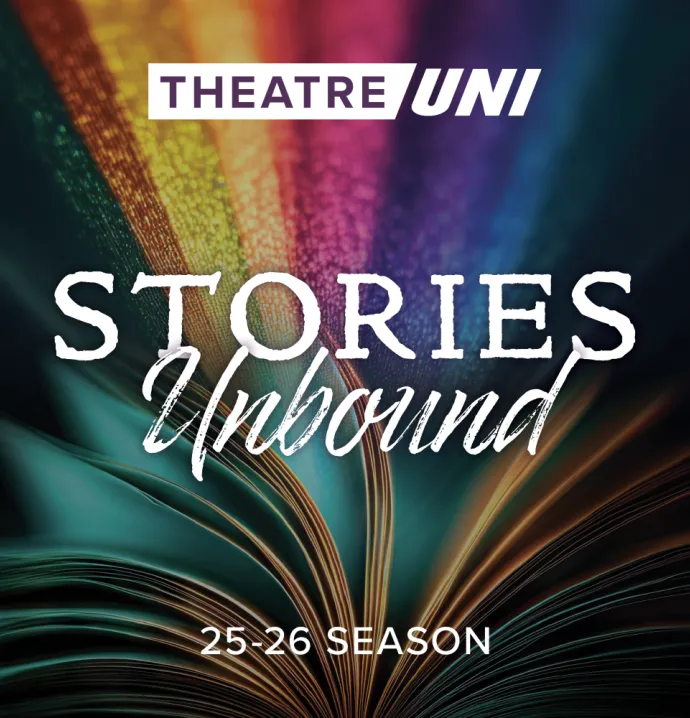

Funkhouser has known she wanted to work in the textiles industry since she was in middle school. Her grandfather was a prolific watercolor painter, but Funkhouser knew her creativity was better expressed in fashion.

“Clothing, in a way, is wearable art,” Funkhouser said.

In her first project with fabric design at UNI her sophomore year, Funkhouser used photoshop to cut one of her grandfather’s paintings into leaf shapes that adorned a cropped blouse with lantern sleeves.

And with graduation coming in the spring, she hopes to use her experience in the program to find a job as a technical designer for an apparel company, where she would help construct patterns and solve fit issues.

While Funkhouser’s passion for the textile industry was clear from an early age, other students in the program never imagined they’d be producing fabric at UNI.

Junior Mia Rampton, a marketing and textiles and apparel major, was one of those students.

“I actually thought I wanted to go into the business side of fashion,’ Rampton said. “So it's really cool to have such an overall education about the program. Now in the future, when I get to go interview for jobs, I have so much more experience than just emphasis on one field.”

Junior Tommy Doyle, a communications and textiles and apparel major, also said he never expected to be making fabric as a student, and said he was a bit anxious about the process.

“The faculty do an awesome job making you feel comfortable, especially for those who don’t have experience doing these sorts of things,” Doyle said. “I’m really looking forward to doing the printing.”

As more and more students use the printer, it will provide valuable knowledge about materials and textiles to students who will go on to pursue a number of careers in the apparel industry, including positions sourcing, acquiring and testing materials. It also gives students experience in a rising trend in fabric production.

“Right now, the industry doesn't do a ton of digital printing, but it is moving in that direction. And someday it will be the main way we print,” Mord said. “There are companies in the United States that are moving in this direction, and having access to this printer definitely makes our students more marketable for those companies.”