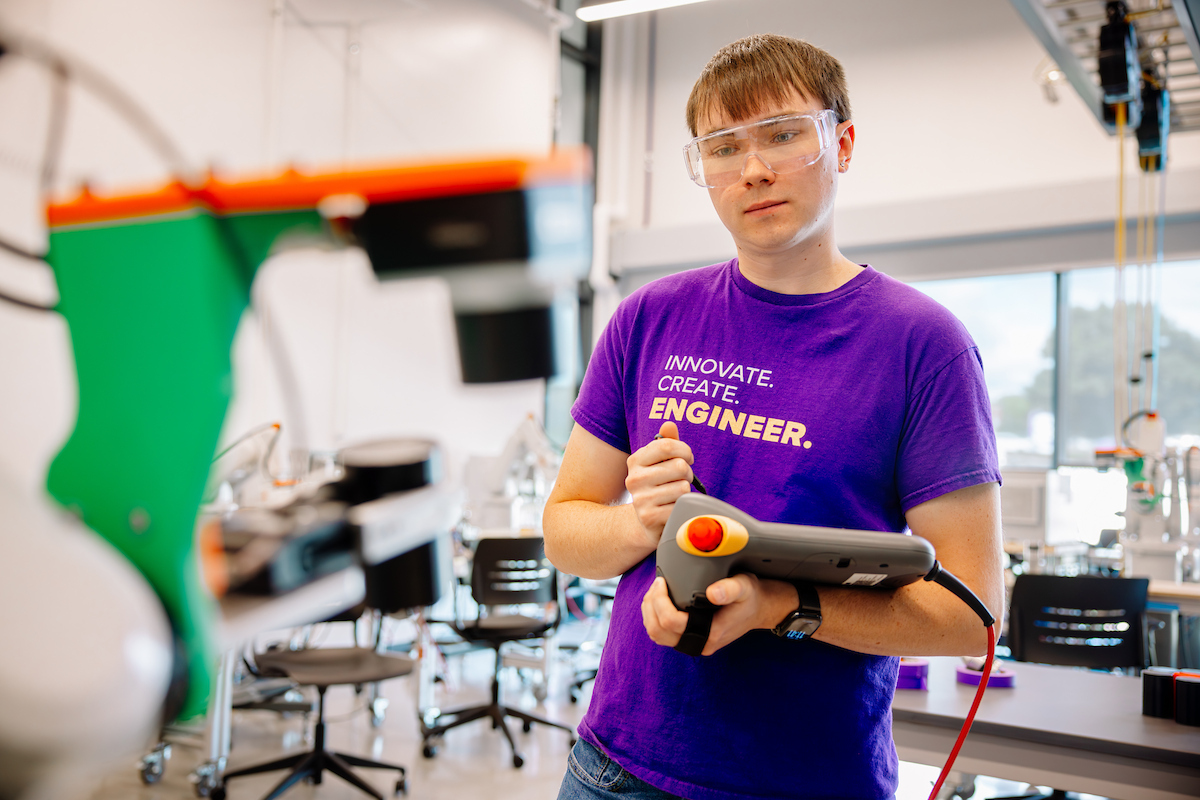

UNI triple major absorbs engineering experience at every turn

UNI triple major absorbs engineering experience at every turn

With three majors and membership in four student organizations, Elijah Yates has fully immersed himself in engineering at the University of Northern Iowa. He is grateful for every opportunity UNI has presented him with, and the ways the university is preparing him for an in-demand career.

“The Applied Engineering building with all the great equipment — it's very relevant to what's currently in industry,” he said. “With the things students use and learn, it’s very easy to apply once you get into your job. I think UNI is a great option for students who maybe don't like the theoretical side of engineering, like super advanced math and physics. We aren't required to take a lot of those really advanced math and physics classes, which is nice, because I like to work with my hands.”

A transfer student, Yates started his higher education journey at Iowa Central Community College in his hometown of Fort Dodge. He hadn’t strongly considered pursuing a four-year degree until Chris Shaw, applied engineering’s recruitment coordinator and academic advisor, visited the community college to talk about UNI’s engineering programs and the updates underway at the Applied Engineering Building. This prompted Yates to visit UNI and see what earning a bachelor’s degree on campus could be like. He was impressed.

“I knew this would be a good place to get a four-year degree,” he said.

The transfer process was an easy transition. UNI took nearly all of his credits, enabling him to avoid repeating classes and declare three majors (electrical engineering technology, industrial management and automation engineering technology).

It’s safe to say the Applied Engineering Building is a second home.

“The Applied Engineering Building here on campus is great,” he said. “We have all this brand-new equipment, and it's always open to students. Working with the department head and other professors —they're super great about opening these lab spaces to students and helping you out if you have a project you're working on.”

Yates has especially enjoyed getting into the cutting-edge lab spaces as soon as he became a Panther.

“At some universities, I know it's not until your third or fourth year you get to be in a lab,” he explained. “I've had classes like metal removal, which is really nice, because I have a lot of interest in machining and working with my hands. We go out in the labs and actually machine stuff and do it by hand and use CNC almost right away. It’s the same thing for all of my electrical classes. We're in the lab the first or second week of school actually working on electrical components, which is really important for me because I like hands-on learning.”

Yates has enjoyed his time in the newly renovated engineering building so much he co-created a student group called UNI Artisans with the sole purpose of introducing non-engineering majors to 3D printers, woodworking equipment and other high-tech machinery at a hobby level.

One of his favorite parts of engineering at UNI is the robots. He grew up competing in robotics competitions and was further exposed to robots at his community college. When he came to UNI, he found the Technology Club that allows him to compete in robotics competitions around the country.

“That's what I really like to do for work is working on automation and industrial robotics,” he said. “Here, I have the opportunity to work with our great metals lab and all the equipment here and the robotics lab. All of that strengthens my interest.”

He dove even further into this love of robotics through a summer internship with Kinetic Technologies in Algona. This gave him experience with robotic welding.

Yates’ second internship took him to Koch Fertilizer in Fort Dodge, where he was able to use a variety of skills he’s learned in class such as machining, 3D modeling and computer-aided design as well as project organization and decision making.

Not only does Yates credit his coursework with helping him secure these internships, but he also sees the enormous benefits of holding officer positions in student clubs. He is the president of the Institute for Electrical and Electronic Engineers (IEEE) and the secretary for the Society of Manufacturing Engineers (SME). Both groups take students on industry tours and connect them with industry professionals. They are also both associated with national conferences where UNI students can network with students and professionals from across the country.

As IEEE’s president, Yates helps organize many tours to local businesses and invites guest speakers to campus.

“That's something I put on my resume,” he said. “It helps me stand out with future careers, future employers, and it's already helped me get some really cool internship offers last year.”