Sculpting the future of public art

Sculpting the future of public art

The stainless steel poured into the sculpture laboratory in the Kamerick Art Building. Not literally poured, like it was molten, but figuratively poured, like there was a ton of it. Because there was. Four tons, to be more precise.

Not that it’s unusual for large quantities of metal to be delivered to the sculpture lab in the summer. That’s when the University of Northern Iowa’s Public Art Incubator is most active, enlisting students to fabricate and erect large-scale public art pieces commissioned and paid for by artists throughout the country.

But this delivery stood out. Those piles of corrosion-resistant alloy stainless steel would eventually form the largest sculpture the incubator ever produced – a massive, 9,000-pound abstract sculpture of a mortar and pestle. The piece was commissioned by the University of Iowa to stand in front of the new College of Pharmacy building and designed by the artist team, Actual Size Artworks, which consists of University of Wisconsin-Madison sculpture professors Gail Simpson and Aristotle Georgiades.

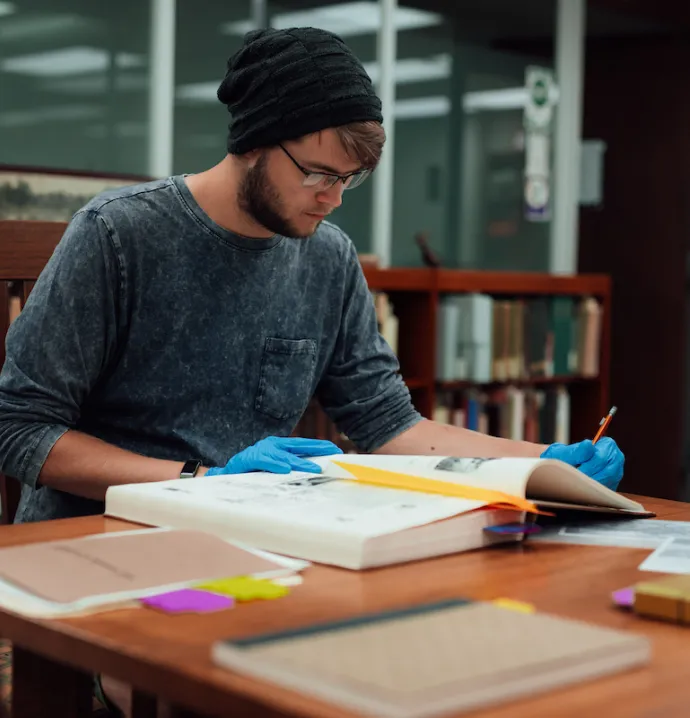

Tasked to construct the sculpture were Incubator faculty Dan Perry, art shop technician and instructor, and Tom Stancliffe, professor of art, along with a team of four students, who were at first daunted by the mountain of metal arriving at the shop.

“It was very overwhelming when the first shipment of metal came in,” said Abigail Hedley, a senior pursuing a BFA in art who has worked in the incubator since her sophomore year. “We knew what the end sculpture would look like, but when you see such a huge mass of metal that's somehow supposed to end up like the model, your brain fries a little bit. Honestly, you feel a little bit of doubt whether or not you’re capable of doing it.”

But Hedley said that the students were reassured by the preparation and experience of Perry and Stancliffe, who spent six months planning, engineering and modeling the sculpture. Ultimately, it was broken down into 23 sections consisting of more than 160 laser cut parts that were assembled into the final piece.

The sculpture was assembled over 10 weeks in the summer of 2017. The days were filled with the type of problem solving posed by the unique challenge of bending large slabs of metal into specific shapes.

“There is no machine available that can magically do that for you, so it all comes down to levers, pulleys and screw clamps. And typically, every one you own,” Stancliffe said. “You apply lifting force here, pry this part over, clamp the other edge inward, have someone press all of their weight down there, and weld it before it all lets go. There is a lot of drama and adrenaline at times.”

Due to construction delays, the sculpture wasn’t installed until July of 2019, when the incubator crew loaded the separate parts of the sculpture onto a semi-truck that delivered them to Iowa City for assembly.

And while the sculpture was the largest project the incubator tackled to date, it was far from the only public art piece produced by the lab.

“Trust me when I say, no summer is quiet in the sculpture studio,” Hedley said.

Your Title Here

Public art is a rapidly growing field in the United States. And the Public Art Incubator is a unique program within the UNI department of art that is meeting this rising demand, serving as a conduit between communities and artists to create art for public spaces.

The incubator has been active since 2011, and the work it produces can be seen on campus, in downtown Cedar Falls and peppered throughout the Midwest and beyond. UNI-fabricated art is installed on both coasts and in the Bahamas.

Each project is distinct in scope, challenging students to problem solve and innovate fabrication processes, while discovering new ways to make art. Students work directly with professional artists and learn how to engage as collaborators in the creation of artworks that help shape communities.

For students, the incubator is an invaluable, hands-on learning opportunity. They are working outside the theoretical bounds of the classroom and producing art with real budgets and deadlines, using advanced techniques that set them up for success after graduation.

“A lot of students leave with a resume that’s better than a lot of people that have been out in the world for a number of years,” Stancliffe said.

Working with the Incubator gave Hedley the skills and confidence to apply for her own public art commission in her hometown of Dubuque. She had to create and present a proposal to a city committee for a sculpture with a $10,000 budget, competing against her own peers. And she won the job.

“If I didn’t work at the Incubator and I didn’t have these experiences, I would have never had the guts to apply for that Dubuque commission,” Hedley said. “The skills I learned here made me feel like I could do this on my own.”

It’s an experience these students could only receive at UNI.

“We haven’t found a program like this anywhere else – a place where you can involve the next generation of artists while giving professional artists opportunities to create work for public spaces with as much control as they want over a project,” Perry said. “When we have students tour graduate programs at universities, even Big 10 schools, they want to come back immediately, because they think we’re set up so well.”

“They come back like homing pigeons, “Stancliffe added. “You can’t keep them away sometimes.”