Micro Scans, Big Opportunities

Micro Scans, Big Opportunities

Imagine you could see right through an animal. You could examine its bones, or the way the muscles are structured, and see the wispy veins and arteries flowing through the animal right before you.

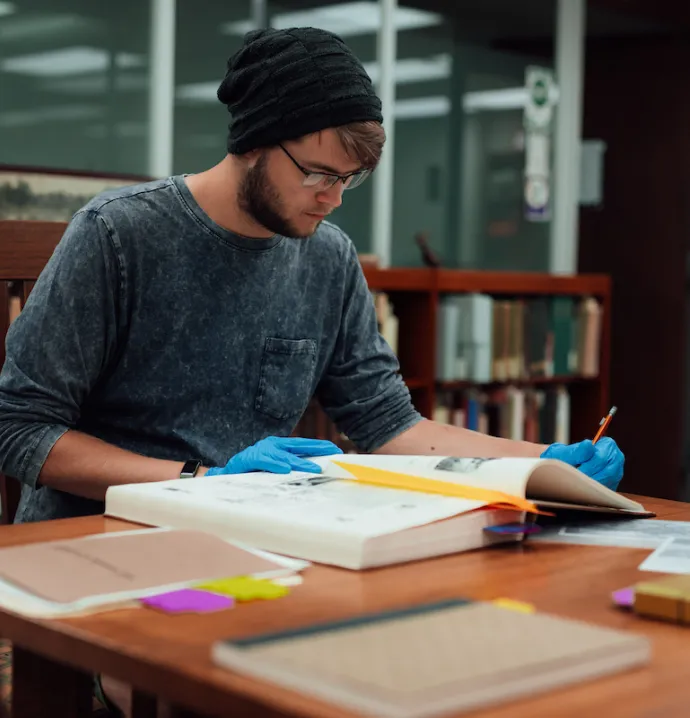

Thanks to a grant from the Roy J. Carver Charitable Trust, University of Northern Iowa biology students no longer have to use their imagination. The UNI Foundation helped to secure the award for just over $300,000 to fund the purchase of a micro-CT scanner, a 3D printer and computer work stations to operate the equipment. Now students can digitally dissect countless organisms, revealing the inner-workings of anatomy in precise detail, which can then be reproduced in 3D for further examination.

The micro-CT will be used to scan small specimens in the vertebrate anatomy class taught by Nathan Bird, assistant professor of biology. Bird says it’s a class that hasn’t changed much in the last hundred years, and it’s time that technology was utilized to make some big changes. Previously, students dissected a shark and a cat, representing the opposite ends of the vertebrate tree. But now, as long as the specimen fits into the 6-inch diameter opening of the machine, students can choose which organism they want to study and perform a digital dissection.

The micro-CT will be used to scan small specimens in the vertebrate anatomy class taught by Nathan Bird, assistant professor of biology. Bird says it’s a class that hasn’t changed much in the last hundred years, and it’s time that technology was utilized to make some big changes. Previously, students dissected a shark and a cat, representing the opposite ends of the vertebrate tree. But now, as long as the specimen fits into the 6-inch diameter opening of the machine, students can choose which organism they want to study and perform a digital dissection.

Scans from the micro-CT can be converted and reproduced on the 3D printer, so students will be able to output a bird skeleton or the organ system of a lizard. They can print a circulatory or nervous system four times larger than actual size to be able to study it in more detail. Vertebrate skulls can be printed, studied and put on display.

Preserved specimens can be obtained from museums, scanned and returned, while not destroying any tissues by dissecting. Then the scans can stay on file and can be rendered at will, so with each class the repository of different specimens available for study will grow.

“It very quickly expands what is available for my students to look at and to play with,” Bird said. “They’re able to really explore the breadth of the vertebrate tree, whereas before they were limited to the ends.”

The micro-CT produces scans by detecting differences in density. It can also be used to scan things other than vertebrates, such as invertebrates, plants and rocks. The small machine can capture more detail through higher resolution images than a large CT scanner, with the capability to capture scans less than a micron in width. Scans are stacked to create a 3D rendering, which can be converted to the file type necessary to be sent through the 3D printer.

Introductory biology classes will also get exposure to the new technology, but students will have to take upper-level courses to get hands-on experience running the equipment. Undergrads and faculty members will utilize the instrumentation for their research projects, and a new class has also been proposed: Biological Design and Function. If approved, students could take scans of organisms and morph them, studying form and function to see if internal systems could be improved with modifications. Basically, students could design their own organism.

The students in Bird’s class will operate the machine themselves, something not many universities provide the opportunity to do. The University of Iowa and Iowa State both have micro-CTs, but they aren’t in the biology department, and students often don’t get to have hands-on experience with them. UNI students in Bird’s class will run the machine by themselves, convert the files and learn how to use the 3D printer, too. It’s resume-building experience coupled with industry-level technology that will get noticed on applications to post-collegiate programs like veterinary, dental, physical therapy and medical schools. “We’re really preparing our students for the next step, giving them a leg up,” Bird said. “It gives them talking points and makes them stand out among applicants.”

The micro-CT was built in Germany and included some add-ons to make it optimized for the university setting. A carousel will allow many specimens to be added at the same time and be scanned one after the other, and a posing module will let students better capture the scans they want. An old dark room was converted to house the micro-CT, 3D printer and computers together conveniently in the same area. “I’m really excited because no one within vertebrate anatomy is doing anything like this. It really puts UNI students at the next level in terms of competing, with that experience they’ll be getting,” said Bird.